Precision Sintered Parts

Precision Sintered PartsRequest A Quote

Tulsa, OK | 918-663-7511https://precisionsinteredparts.net

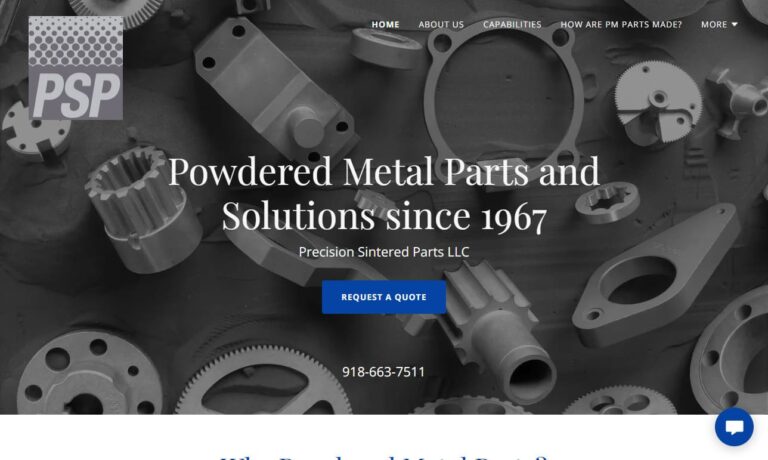

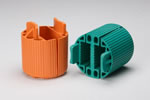

Founded in 1967, Precision Sintered Parts has the experience in producing powder metal parts and providing solutions for many different applications. Over the past five decades, we have provided our products and services to businesses across a multitude of industries. Markets we have served and continue to serve include sports and recreation equipment, agricultural equipment, power tools, manufacturing equipment, and more. We can manufacture powder metal parts in a broad range of configurations. Whether you require a simple, uniformly dimensioned shape or a complex, multi-level component, we have the equipment and the expertise to make it happen. We manufacture powdered metal parts with footprints up to 6.5 in.2 (42.3 cm.2) and tolerances as close as 0.001 in. (0.025 mm.) If you require a certain material, we can produce these parts out of various metals such as iron, steel, and brass. In addition to custom components, our parts are available in standard forms. These parts include holes, tapers, fillets, chamfers, flanges, hubs and studs. No matter what part you need, we are committed to continuous improvement in the powdered metal industry, and we aim to be our clients’ supplier of choice by personalizing our service according to their needs. We are ISO 9001:2015 certified, and have been an ISO 9001 certified manufacturer since 2004. Our team has over 100 years of combined experience, and can provide information in a timely manner on our capabilities, project estimates, production schedules, and delivery dates. To learn more, we are just a call or email away. Coming up with powdered metal parts design solutions is our passion, so contact us today and tell us about your project.

Cold Headed Parts

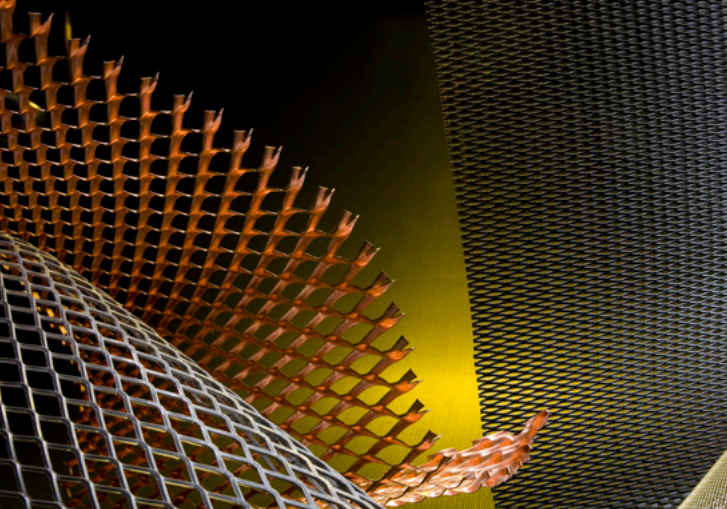

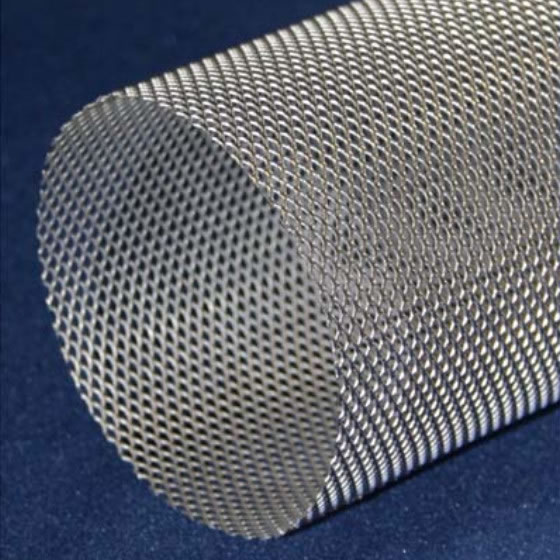

Cold Headed Parts Expanded Metals

Expanded Metals Metal Spinning

Metal Spinning Powdered Metal Parts

Powdered Metal Parts Roll Forming

Roll Forming Springs

Springs Wire Forms

Wire Forms Wire Mesh

Wire Mesh Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services