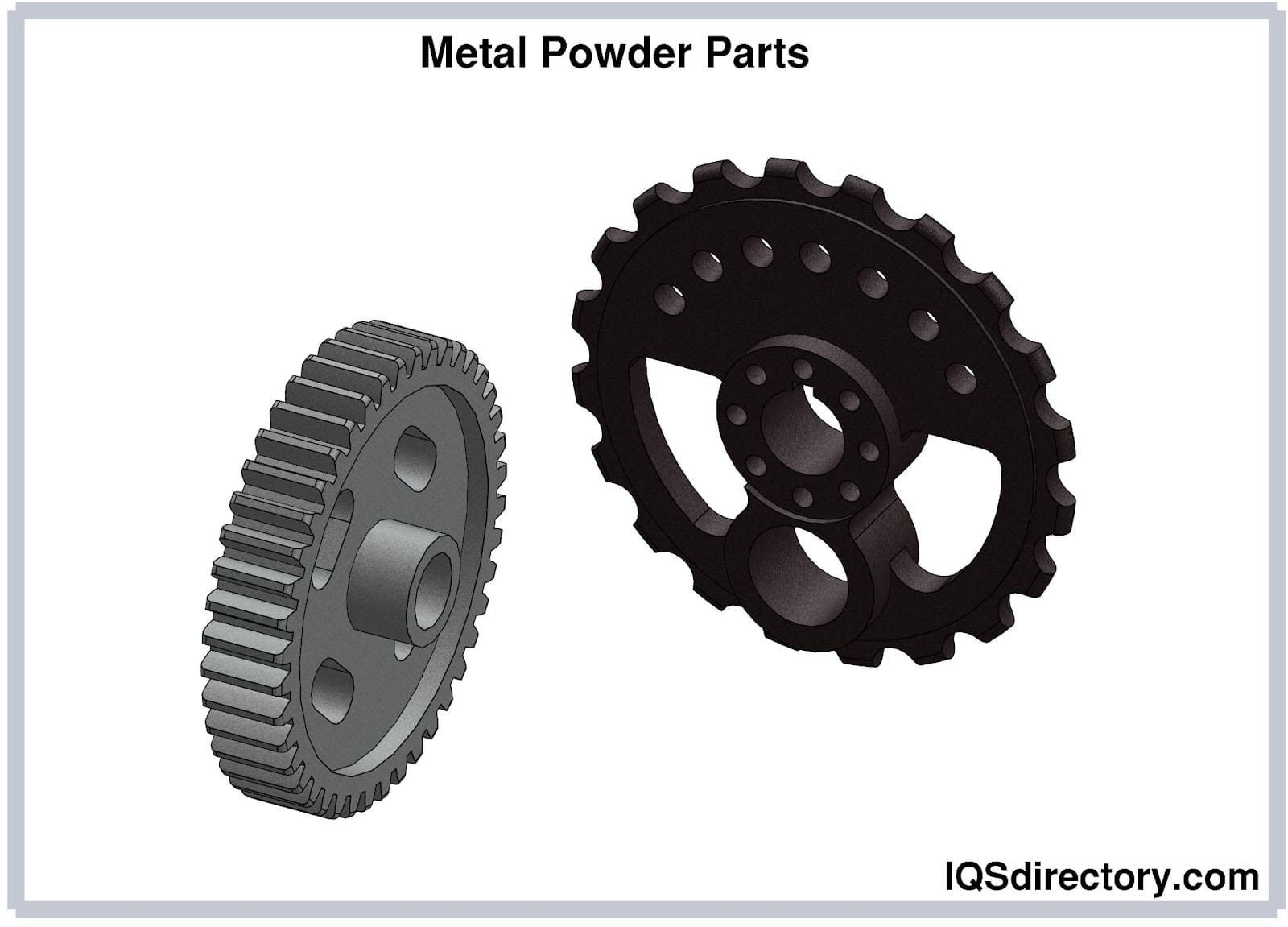

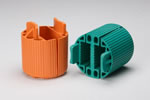

Metal powder parts are made from very fine, compressed metal powders which are then sintered to take their final shape either from molds or dies. Parts made from metal powder fabrication allow for the production of items with intricate geometries. The figure below shows some of the parts that are made from metal powder. Read More…

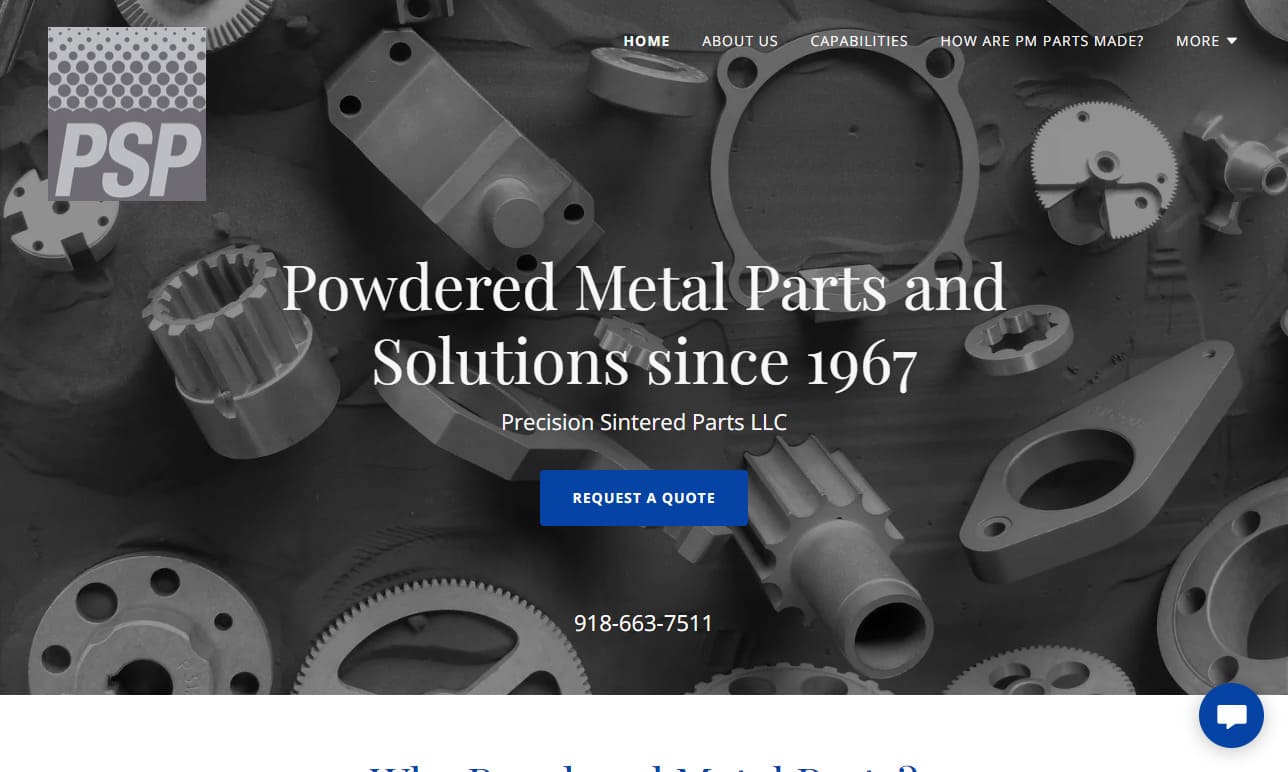

Since 1967, PSP has been a leader in small, intricate custom powdered metal parts for a wide range of industries, such as Sports & Recreation, Power Tools, Industrial Equipment, Oil & Gas.

Liberty Pressed Metals is a designer and producer of Powder Metals (PM) components for use in various industries, such as automotive, lawn and garden, office equipment, power tool, home appliances, and more. Our process boost product strength, precision, and durability. We are ISO 9001: 2015 certified. Our quality management system assures top-quality sourcing of materials, as well as unmatched...

Metaltech, Inc. has been in the metal powdered industry since 1989 in the heart of Dubois, Pennsylvania known as the capital of powdered metal. Our mission is too work with our customers to determine the efficient and economical method of production. We want to bring you the best product at the best price. Call today or visit our website for more information!

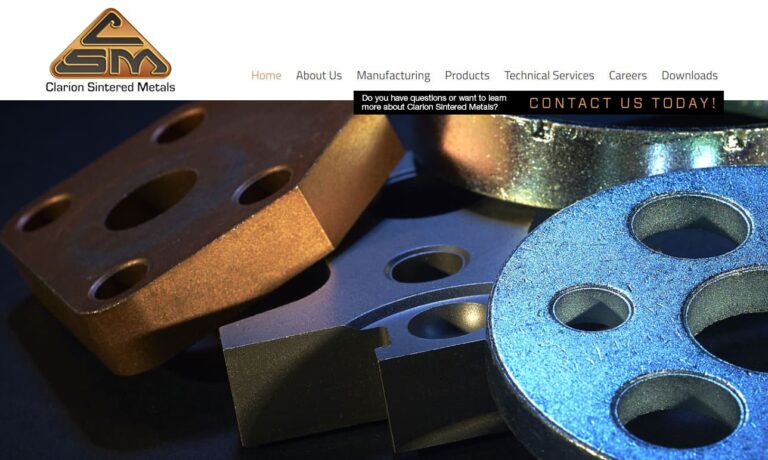

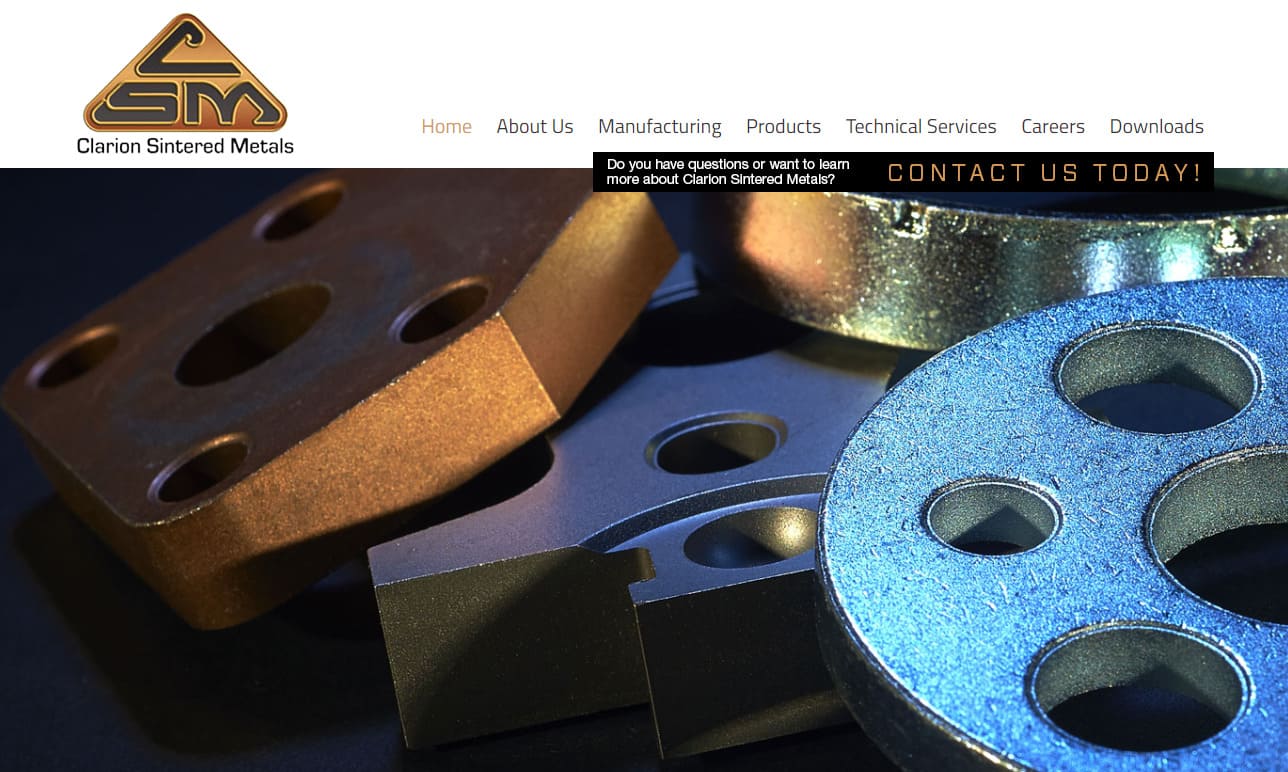

Founded in 1947, Clarion Sintered Metals is a trusted source for powdered metal parts. Clarion’s powder metallurgy specialists assist in the manufacturing of a variety of precision, cost-effective parts and components to ensure you receive the best in quality. From design assistance to finished sintered metal parts, ISO/TS 16949: 2002 registered Clarion has the expertise to meet any challenge.

Our metal injection molding cannot be topped! We have years of field industry experience that we want to put to work for you. It is our mission that we will be able to offer high quality customer service as well as products that will withstand the tests of time to provide lasting value. For more information on what we may be able to do for you, get in touch with our customer service department...

Our design team develops and tests specific materials that are best suited for the intended application. By carefully reviewing various performance data, we can determine the most suitable material characteristics that will provide optimum performance during the product's life cycle. Our design group reviews our customers' existing processes and components, and in many cases, can design a powder...

Connor Corporation is a leading manufacturer of powdered metal parts. We offer a wide range of metals including non-ferrous metals, stainless steel, steel alloys, and specialty blend alloys. Bring us your customs designs and our team will work with you to fill all of your needs. Connor Corporation also offers various secondary operations including plating and finishing operations, all of which...

More Metal Powder Part Manufacturers

Common parts created from metal powders include gears, bearing housing, bushing, automotive parts, electrical parts, motorcycle parts and also parts of the sewing machine. Metal powder parts can also be utilized for less- common applications such as gas filters, electrical connectors, and heat shields for spacecraft during re-entry. The parts made from metal powders can be completely functioning components or they can simply be utilized as prototypes. Alloyed metals like iron, stainless steel, titanium, copper, tin, tungsten, aluminum and molybdenum are commonly-used base metals to create metal powder parts.

Making Metal Powder

The first step in metal powder parts production is making the powder itself. Metal powders have traditionally been created through solid state reduction. In this process, selected ore is crushed, usually combined with carbon, and then passed through a furnace. When the carbon and oxygen in the powder are removed in the furnace, a cake- like sponge metal is left behind. This cake is crushed, cleaned of all non-metallic material and then sieved to produce the powder. The resulting sponge-like irregular particles are soft, easily compressible and provide strong pre-sinter strength. The purity of the powder depends on the purity of the raw components because there is no refining process involved.

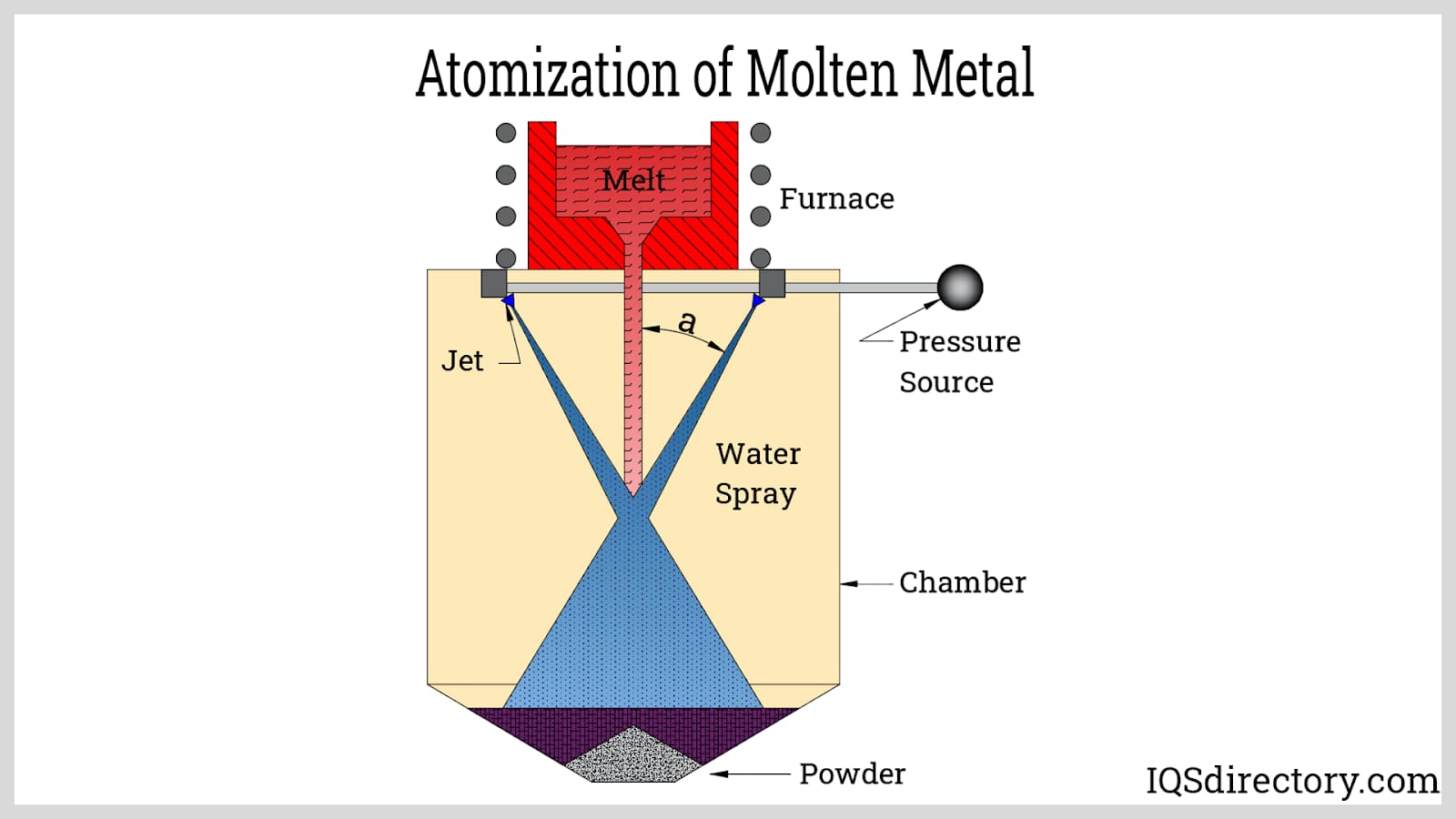

Metal powders may also be created through atomization, electrolysis, and chemical processes. In atomization, metals are melted down and disintegrated while being poured through jets of water or gas, the metal then solidifies as small droplets. In electrolysis, electricity is used to break metals down into a powder form. This process is comparatively expensive, and requires more-specific metal conditions in order to produce an effective powder. Chemical processes, including thermal decomposition and oxide reduction, may also be employed to create metal powders.

Metal Powder Parts Manufacturing Processes

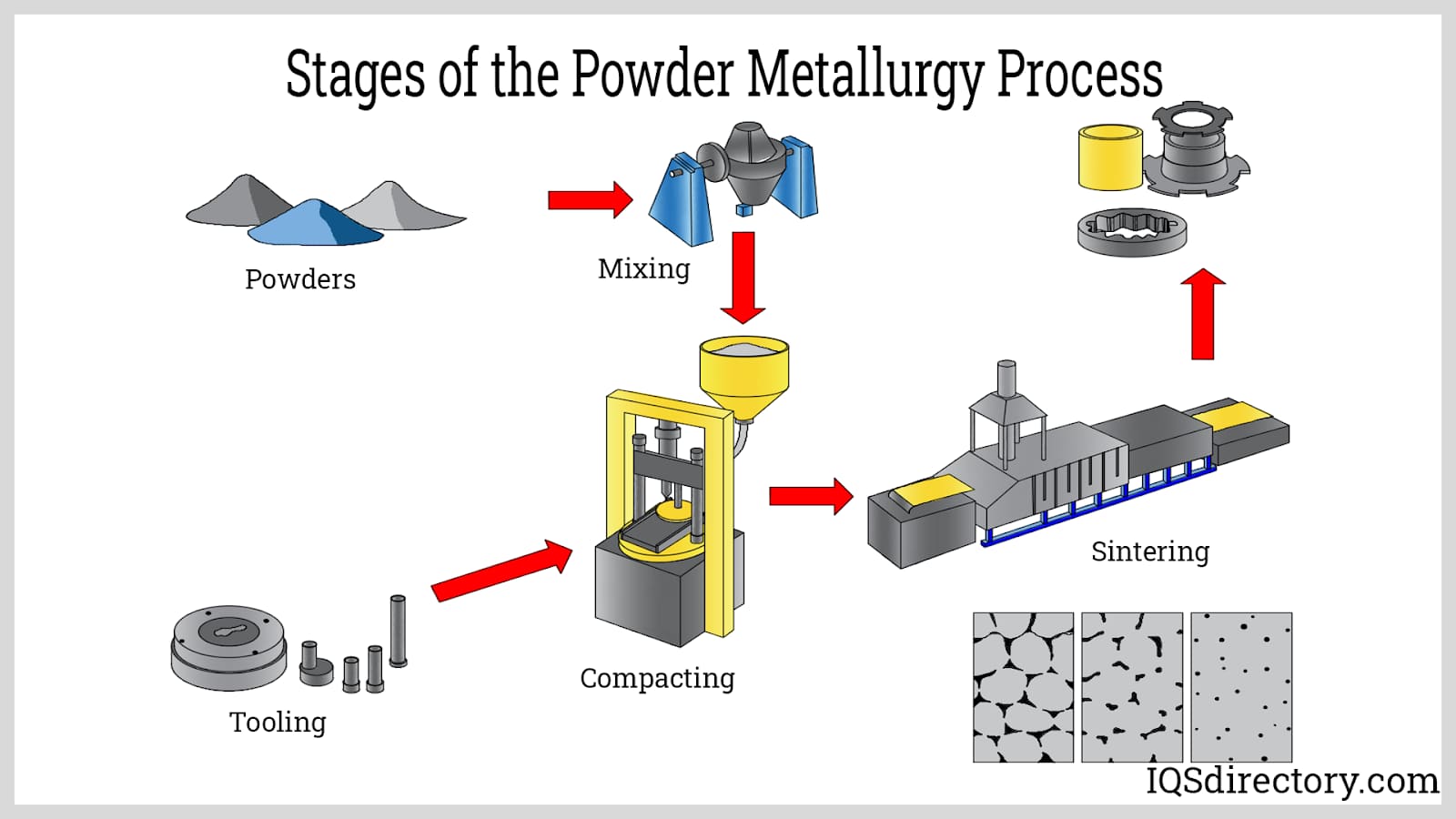

There are a number of processes that can be used to produce metal powder parts. Some of the techniques used to create metal powder parts include hot isostatic pressure, powder forging, metal injection molding, and die compaction. We briefly discuss each of these techniques in greater detail below.

In powder forging, metal powder is transferred into a metal preform. This preform material is then forged into a specific metal part while being confined in a die.

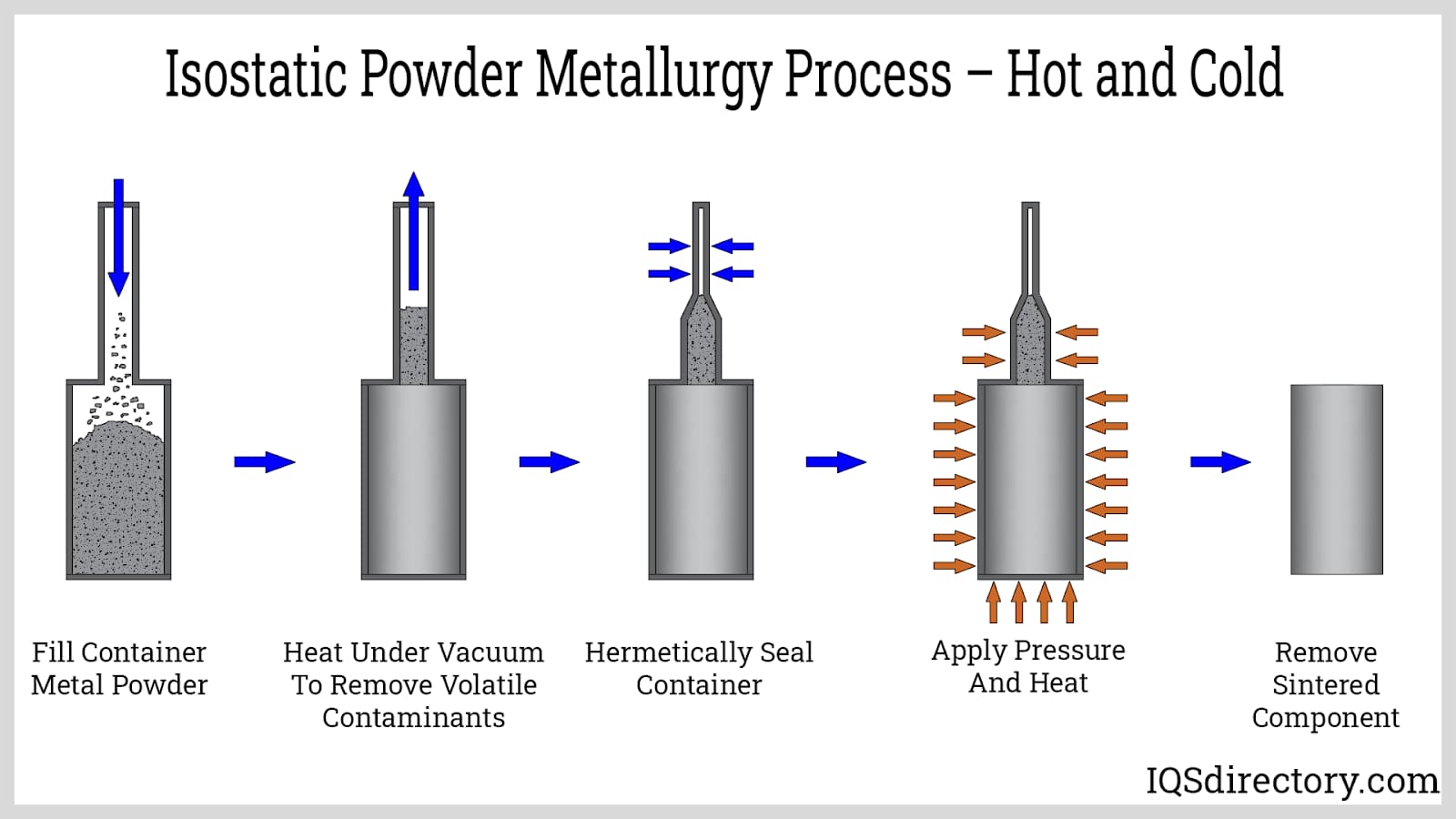

With hot isostatic pressure, a metallic powder is placed into a metal mold. The mold is then sealed, vibrated, then pumped to remove all the air. The mold is put into a hot isostatic press which is heated to homogenous temperature and internal pressure is raised using an external gas pressure. A finished object produced using this specific method is guaranteed to possess the right shape and density. The component’s mechanical characteristics are as-wrought or superior.

Metal injection molding (MIM) starts with mixing a metal powder with a binder (binding material) to create a feedstock (a raw material that gets altered through an industrial process). This feedstock is then injected into a mold where it solidifies to produce a desired object.

Die compaction is another method for producing items from metal powders. Under this method, metal powders are compressed to form a material known as “green compact.” This material is then set into a die and sintered (a process of using heat and pressure to form a solid material before it melts to the point of liquefaction from these forces) to produce a desired item. Secondary heat treatments are frequently employed after sintering to improve mechanical characteristics and dimensional accuracy.

Metal Powder Parts Design Considerations

- The part must be constructed in a way that makes it simple to expel from the die. Sidewalls must be perpendicular, and the hole axes must be parallel to the die's opening and closing directions.

- Parts created through this process tend to be more porous than those created through other methods.

- Metal powder parts have a greater tendency to be produced with blisters or blowouts (bare surfaces) than those created through other processes.

- Metal powder parts can be created using a variety of metal alloys.

- The various metal powder parts manufacturing processes minimize machining time and issues by producing consistent parts.

- The methods used to create metal powder parts produce little waste; up to 97% of raw material may be used.

Choosing the Right Metal Powder Parts Manufacturer

To make sure you have the most positive outcome when purchasing metal powder parts from a metal powder parts manufacturer, it is important to compare at least 4 to 5 companies using our list of metal powder part manufacturers. Each metal powder part manufacturer has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each metal powder part business website using our patented website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple metal powder part businesses with the same form.

Cold Headed Parts

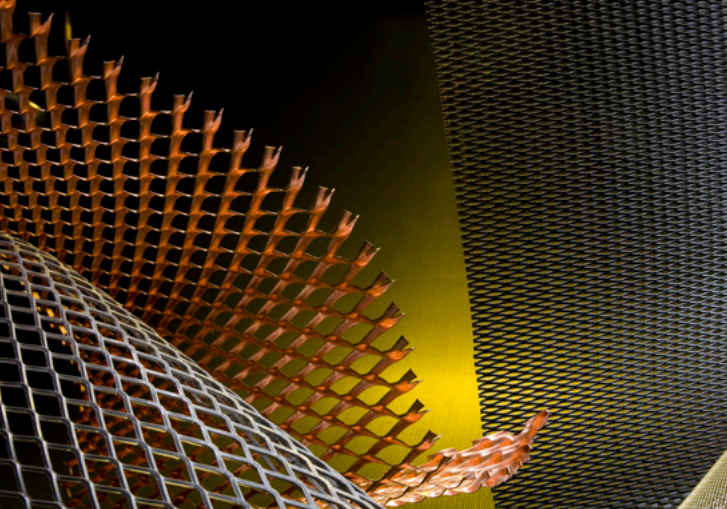

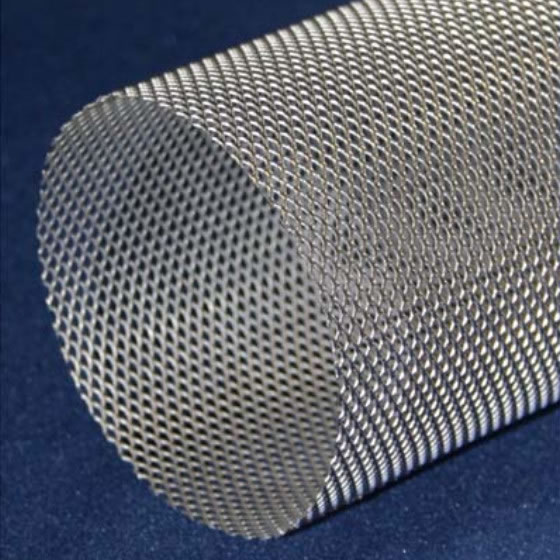

Cold Headed Parts Expanded Metals

Expanded Metals Metal Spinning

Metal Spinning Powdered Metal Parts

Powdered Metal Parts Roll Forming

Roll Forming Springs

Springs Wire Forms

Wire Forms Wire Mesh

Wire Mesh Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services