Powder metal gears are found in aerospace, agricultural, automotive, building and construction, marine transportation, material handling, medical, military, petrochemical, pharmaceutical, power generation and robotics industries. The demand for application specific metal gears has led to the introduction of several types or styles such as anti-backlash, bevel, miter, chance, cluster, differential, helical, herringbone, hypoid, internal, planetary, spur and pinion gears. While these mechanisms can be produced in a number of machining processes, powder metal parts provide several advantages over traditional gear manufacturing methods. Read More…

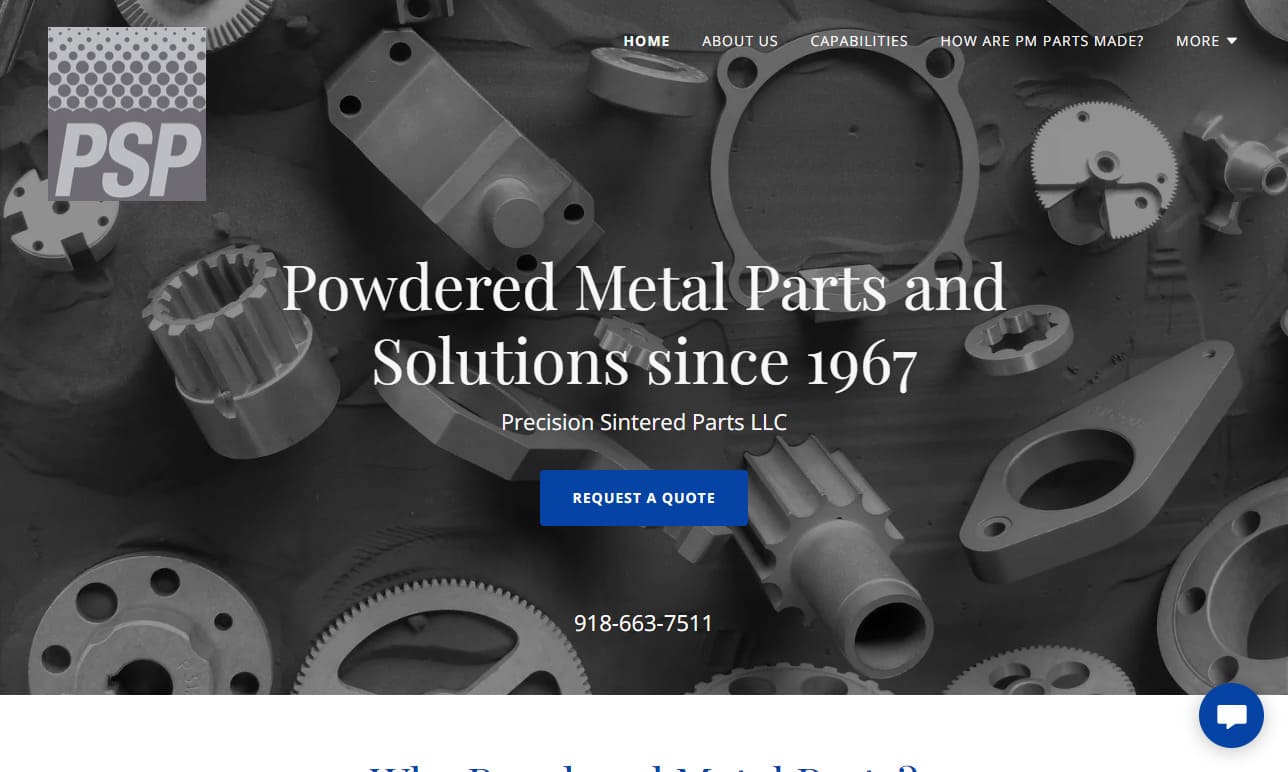

Since 1967, PSP has been a leader in small, intricate custom powdered metal parts for a wide range of industries, such as Sports & Recreation, Power Tools, Industrial Equipment, Oil & Gas.

Liberty Pressed Metals is a designer and producer of Powder Metals (PM) components for use in various industries, such as automotive, lawn and garden, office equipment, power tool, home appliances, and more. Our process boost product strength, precision, and durability. We are ISO 9001: 2015 certified. Our quality management system assures top-quality sourcing of materials, as well as unmatched...

Metaltech, Inc. has been in the metal powdered industry since 1989 in the heart of Dubois, Pennsylvania known as the capital of powdered metal. Our mission is too work with our customers to determine the efficient and economical method of production. We want to bring you the best product at the best price. Call today or visit our website for more information!

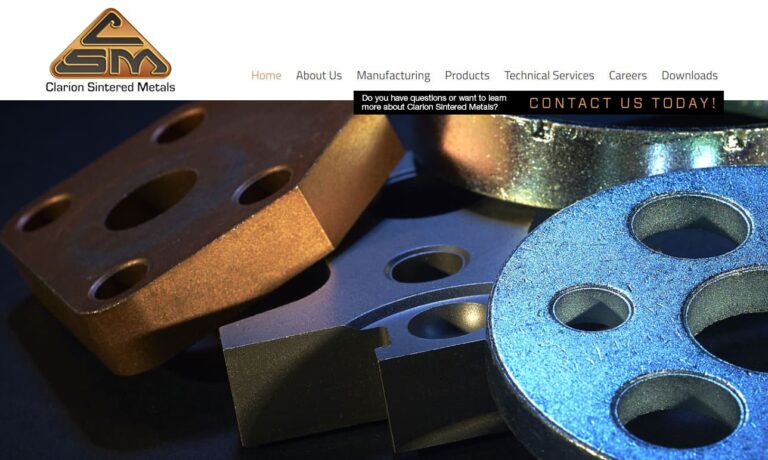

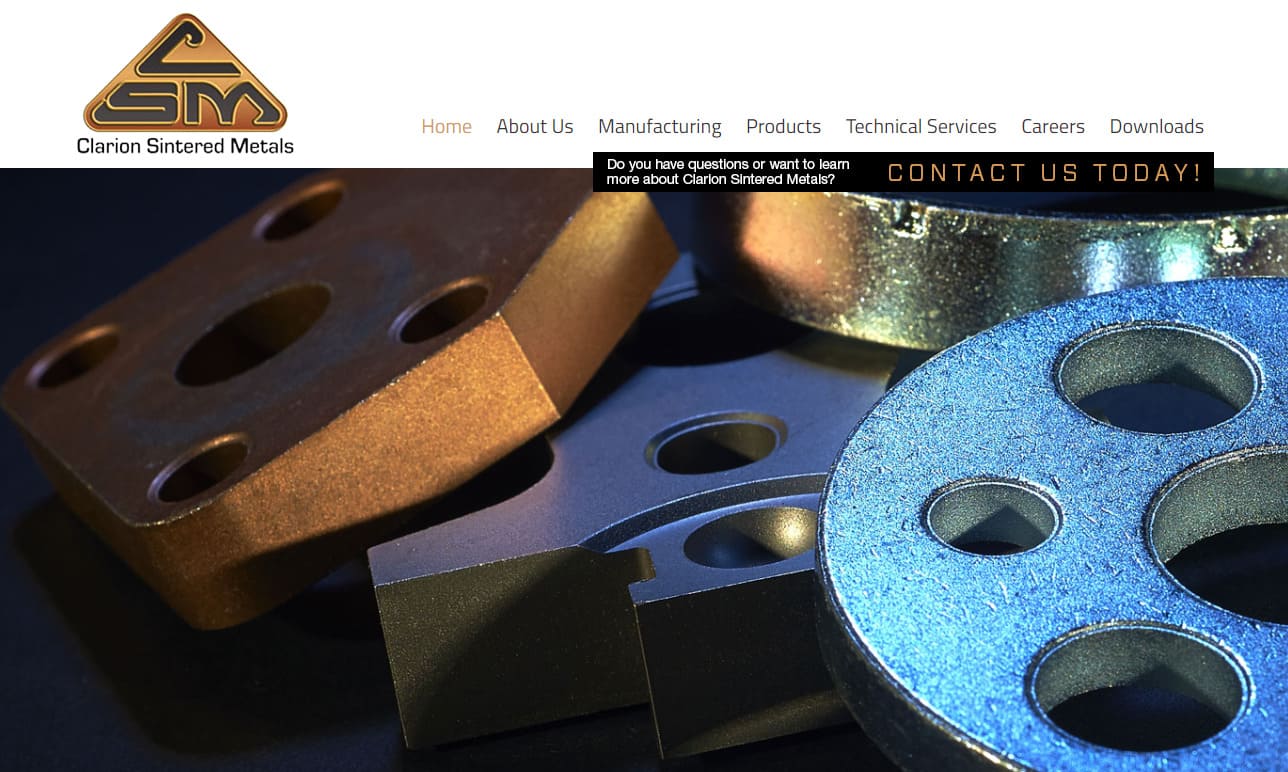

Founded in 1947, Clarion Sintered Metals is a trusted source for powdered metal parts. Clarion’s powder metallurgy specialists assist in the manufacturing of a variety of precision, cost-effective parts and components to ensure you receive the best in quality. From design assistance to finished sintered metal parts, ISO/TS 16949: 2002 registered Clarion has the expertise to meet any challenge.

Our metal injection molding cannot be topped! We have years of field industry experience that we want to put to work for you. It is our mission that we will be able to offer high quality customer service as well as products that will withstand the tests of time to provide lasting value. For more information on what we may be able to do for you, get in touch with our customer service department...

Our design team develops and tests specific materials that are best suited for the intended application. By carefully reviewing various performance data, we can determine the most suitable material characteristics that will provide optimum performance during the product's life cycle. Our design group reviews our customers' existing processes and components, and in many cases, can design a powder...

Connor Corporation is a leading manufacturer of powdered metal parts. We offer a wide range of metals including non-ferrous metals, stainless steel, steel alloys, and specialty blend alloys. Bring us your customs designs and our team will work with you to fill all of your needs. Connor Corporation also offers various secondary operations including plating and finishing operations, all of which...

More Powdered Metal Gear Manufacturers

Most of the benefits arise specifically from the versatility allowed in press-and-sinter processing. The ability to produce multilevel gears, internal configurations and very close tolerance components eliminate or reduce the need for secondary operations, thereby cutting costs and saving time.

The uniformity and reproducibility of these parts gives further economic value to powdered metal gears. Additionally, the porosity of sintered elements such as these allows for oil or resin impregnation which creates self-lubricating components, a feature that prolongs the working life of not only the gear, but the motor of which it is a part. The porosity, which can be closely controlled to suit specific requirements, also dampens sound and reduces the weight of a given part.

There are three basic steps to powder metallurgy, the process used to create powder metal gears. First, any of a number of techniques including atomization, flaking, pulverization, chemical reduction and electrolytic are used to reduce the initial raw metallic materials to a fine dust or powder. Specific amounts of this powder are then placed into the compaction die or mold where pressure is applied from both above and below in precise amounts relevant to the specific materials and intended use of the finished gear. This mold is pre-formed and results in the desired gear shape. After this form is ejected from the die, sintering is used to fuse the powder particles together.

The parts are placed on a moving belt which draws them through a controlled-atmosphere furnace, heating the compressed powder to just below the melting point of the raw materials. This temperature varies greatly, though a general rule is to use a temperature that is 2/3 that of the melting point for the primary metal. In this manner, the mechanical bonds of metal powders are converted into metallurgical bonds creating a solid mass from the powder. Gears can be composed of either a single metal or a composite material.

Common metals include aluminum, brass, bronze, cast iron, carbon or alloy steel, magnesium and titanium. Beyond materials, further considerations include, gear type, number of teeth, design units, tooth form, direction, gear center, pressure angle, gear features and mounting requirements.

Cold Headed Parts

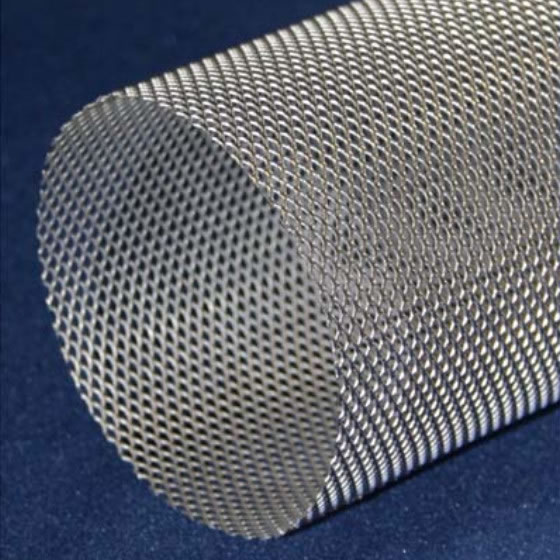

Cold Headed Parts Expanded Metals

Expanded Metals Metal Spinning

Metal Spinning Powdered Metal Parts

Powdered Metal Parts Roll Forming

Roll Forming Springs

Springs Wire Forms

Wire Forms Wire Mesh

Wire Mesh Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

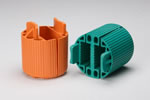

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services